Services

We have designed, fabricated, and installed conveying equipment and ancillary steelwork for New Zealand and Australia's bulk materials handling industry for over thirty years. Let us know how we can help provide a solution for your project today.

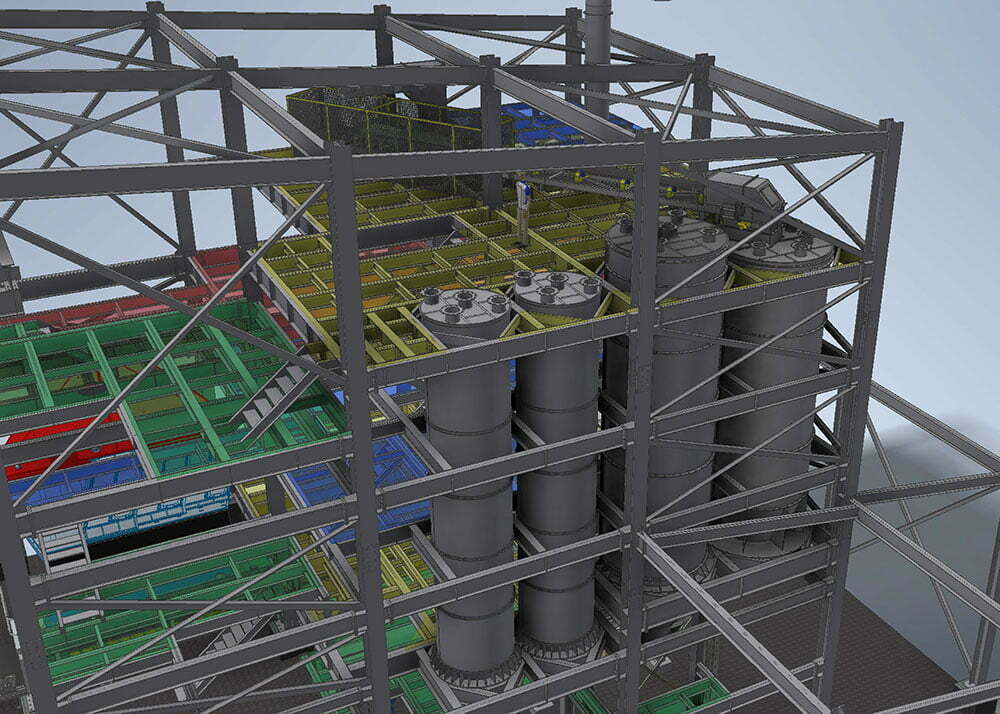

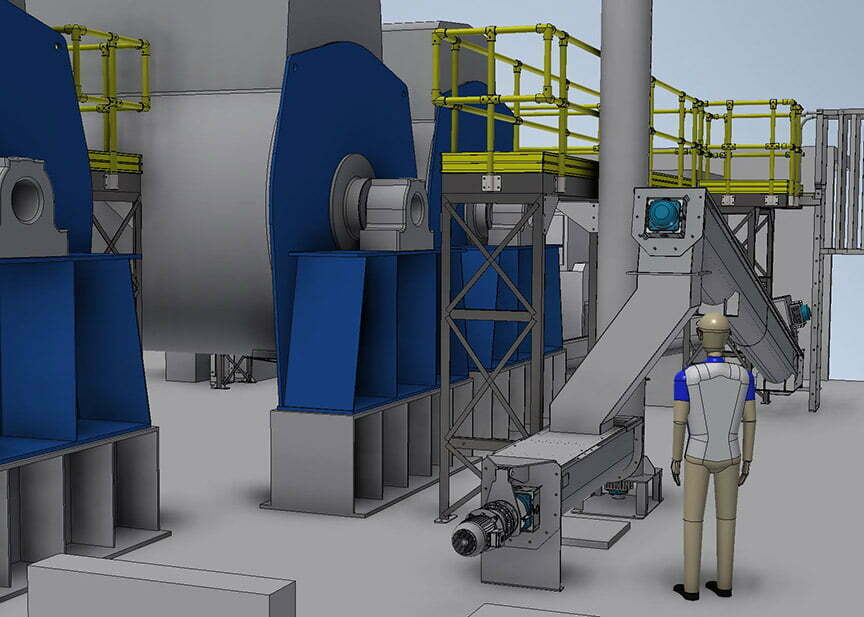

Design

We operate a complete in-house design service where our experienced team creates a solution for your project requirements using the latest technology. We identify how the equipment will function in its target environment alongside the existing infrastructure and processes and identify required amendments. Our team's significant exposure to various materials handling applications and their expertise helps us to make the best decisions during the conceptual stage.

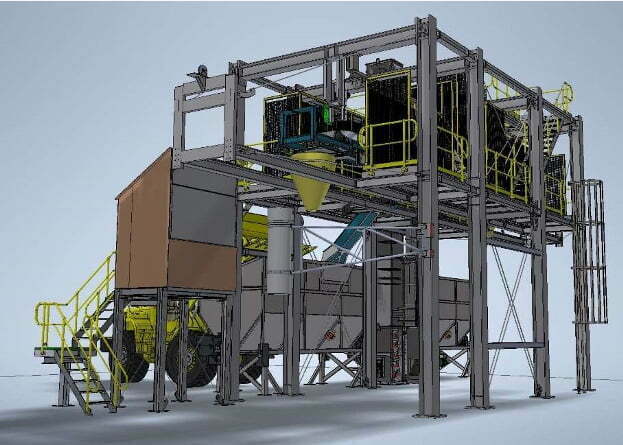

Manufacture

Our workshop allows us to manufacture custom-built machinery. With an 1150 m2 floor area and two overhead gantry cranes, we can carry out large, multiple projects. Our workshop includes a CNC teach lathe, a turret mill, a large guillotine, and specialised equipment for fabricating conveying systems. Many in our workshop team have been with us for over a decade, bringing maturity and valuable fabrication experience.

Install

We regularly install our manufactured equipment on a client's site. The members of our install team are selected to complete an installation based on experience and appropriate skillset. We work closely with our client's operators during the commission, recognising their expertise.

Project Solutions

We have experience in providing project management on complete turnkey solutions. It usually involves developing a system from scratch, using our client's core equipment and specialised processing machinery. We also have access to a network of international suppliers. We work with you to ensure that the capital expenditure meets the life-cycle requirements, including operation and maintenance costs and plant life expectations.