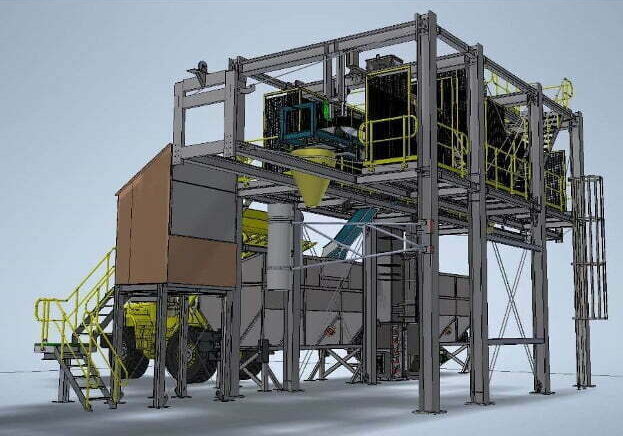

Fertiliser Blending, Screening, and Dispatch Facility

We were engaged to deliver a complete fertiliser handling solution for a new greenfield store, developed to provide storage and efficient dispatch of fertiliser to shareholders. Our scope included the fabrication, installation, and commissioning of blending hoppers, a bucket elevator screen, a lump breaker, belt conveyors, structural steel, and chutes.

Challenges

The client required a purpose-built facility capable of receiving, blending, and dispatching fertiliser products reliably and at scale. Fertiliser handling presents several challenges — including controlling dust, breaking down lumps to ensure consistent product quality, and designing equipment robust enough to withstand the corrosive and abrasive nature of fertiliser materials.

Our Solution

We designed and delivered an integrated system tailored to fertiliser blending and dispatch; this included blending hoppers for product consistency, a bucket elevator screen and lump breaker to maintain product quality, belt conveyors for efficient transfer, and robust structural steel and chutes to support safe, long-term operation. The equipment was fabricated, installed, and commissioned to meet the client's operational requirements.

Outcome

The completed facility provided the client's shareholders with a reliable, purpose-built fertiliser blending and dispatch store. The system ensures consistent product quality, efficient loading and unloading, and safe, low-maintenance operation. With CIL's expertise in fertiliser handling, the facility is designed to deliver long-term performance and support future operational needs.

Related Equipment

Get in Touch

Whether you’re after technical details, pricing, or just want to understand your options, use the form below to send us a message. We’ll get back to you with the support you need.